After-hours emergency services are provided.

Commercial facilities do not slow down. Trucks roll in. Forklifts move fast. Staff work around the clock. That is why dock and door systems need to keep up without fuss. When equipment fails, everything backs up. Time gets wasted. Risks go up.

J&S Garage Doors focuses on commercial only dock and door solutions that are tough, reliable, and made for daily abuse. These systems are not about bells and whistles. They are about safety, speed, and keeping operations on track. So, let us break down the key components that keep commercial spaces running smoothly.

Dock levellers do one simple job. They bridge the gap between the dock and the trailer. But that simple job matters a lot.

Without a solid leveller, loading turns into a headache. Forklifts bounce. Pallets shift. Workers strain. A properly installed dock leveller creates a smooth path. As a result, loading gets faster and safer.

Hydraulic dock levellers offer easy control and smooth movement. Mechanical dock levellers are rugged and budget friendly. Both work well when installed right. Either way, a good leveller keeps freight moving without drama.

Trailer movement is no joke. One early pull out can cause serious injuries and damage. That is where dock restraint systems step in.

These systems lock the trailer in place during loading. Add communication traffic lights, and things get even safer. Red means stop. Green means go. No guesswork. No mixed signals.

As a result, dock workers feel more confident. Drivers know exactly when it is safe to move. Fewer accidents. Smoother workflow.

Parking garages can feel chaotic. Tight corners. Poor visibility. Constant back and forth traffic.

Underground parking traffic light systems bring order to the chaos. They control vehicle flow and reduce collisions. Drivers know when to stop and when to proceed. That lowers stress and improves safety.

These systems are a smart fit for commercial buildings, condos, and large facilities with shared parking areas.

Dock seals might not look exciting, but they do heavy lifting behind the scenes. They seal the space around the trailer, blocking out wind, rain, and snow.

That means better temperature control. Less energy loss. More comfort for dock workers. Over time, energy savings add up. So do lower heating and cooling bills.

For temperature sensitive operations, dock seals are a must have.

Some docks handle different trailer sizes all day long. That is where dock shelters shine.

Instead of sealing tightly like dock seals, shelters form a flexible enclosure. They still block weather and debris while allowing easy access. This setup works well for high traffic docks that need versatility.

In short, dock shelters keep things moving without slowing anyone down.

Every truck backs into a dock with force. Over time, that impact can damage both the building and the trailer.

Dock bumpers absorb that shock. Rubber and steel faced bumpers protect dock walls and frames. They reduce cracks, dents, and structural wear.

Think of them as cheap insurance for your dock.

Hydraulic pumps and pistons power many dock systems. Levellers, restraints, and other equipment rely on them.

When hydraulics fail, everything slows down. Leaks, uneven movement, or strange noises are warning signs. Regular service keeps these systems strong and reliable.

Proper maintenance also helps avoid sudden breakdowns that can shut down operations.

Mechanical docks with springs are still widely used. They are tough, simple, and proven.

These systems rely on heavy duty springs to lift the platform. But spring tension must be set just right. Too loose or too tight causes problems.

Skilled technicians make sure everything stays balanced. That keeps the dock safe and functional day after day.

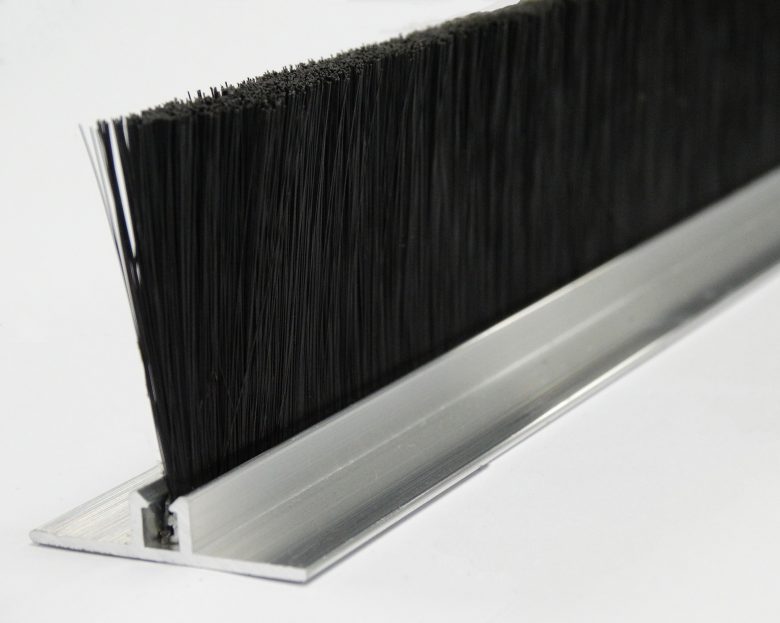

Even small gaps cause big issues. Dust sneaks in. Cold air rushes through. Pests find a way.

Dock brushes and rubber seals close those gaps. They improve cleanliness and help control temperature. This is especially important for food handling and pharmaceutical facilities.

Sometimes, it is the small upgrades that make the biggest impact.

Safety starts with visibility and control. Wheel chocks stop trailers from rolling. Yellow guards protect walls and equipment. Caution signs warn everyone of potential hazards.

Together, these tools create a safer dock environment. They support safety compliance and reduce accidents. Clear signals help workers stay alert.

High speed doors are built for fast paced commercial spaces. TNR, HORMANN, and RYTEC doors open and close quickly. That keeps workflow moving.

They also help with temperature control and cleanliness. Dust stays out. Air stays in. These doors work well in warehouses, cleanrooms, and manufacturing plants.

With proper installation and service, they handle constant use without breaking a sweat.

Commercial dock equipment is not a weekend project. Poor installation leads to faster wear and higher risk.

Professional installation ensures systems work as intended. It also protects your investment long term. Fewer breakdowns. Less downtime.

J&S Garage Doors understands commercial demands. Their team helps businesses choose the right systems and installs them with care.

Commercial operations never stand still. Dock and door systems need to keep up.

From levellers to high speed doors, the right setup supports safety, efficiency, and growth. With proper equipment and expert service, facilities stay ready for whatever comes next.

Warehouses, logistics centres, manufacturing plants, and distribution hubs all rely on dock systems daily.

At least once a year. High traffic facilities may need more frequent inspections.

Yes. They prevent trailer movement and reduce the risk of serious accidents.

They are. Fast opening and closing limits air loss and helps maintain indoor temperatures.

In many cases, yes. Older docks can often be retrofitted with modern equipment.